BW-Fixators® – Series LK:

The BW-Fixators® of series LK have been invented especially for the anti-vibrant and loose alignment of machines. Due to a exceedingly long setting range of 10 mm uneven surface can be compensated easily.

With this series are two sizes availabe with load values from 30.000 N up to 55.000 N.

The adjustment is easy in opertation and safe from unintentional adjustment (e.g. vibration). The applications of these BW-Fixators® can be customized by a lot of diffrent variants. Diffrent isolation plates, made from multiple layers jute fabric combined with special bitumen under high pressure or isolation plates made of polyurethane allow the anti-vibrant alignment.

The time for the alignment of your machine will be reduced significant. If the machines needs to be re-adjusted because of foundation shifting or shrinkage, it can be done simply and fast.

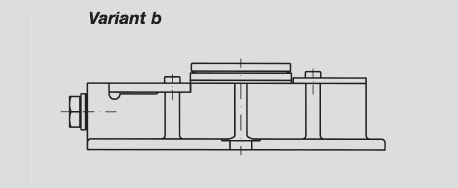

The alignment can be done loose or with diffrent anchors.

Downloads

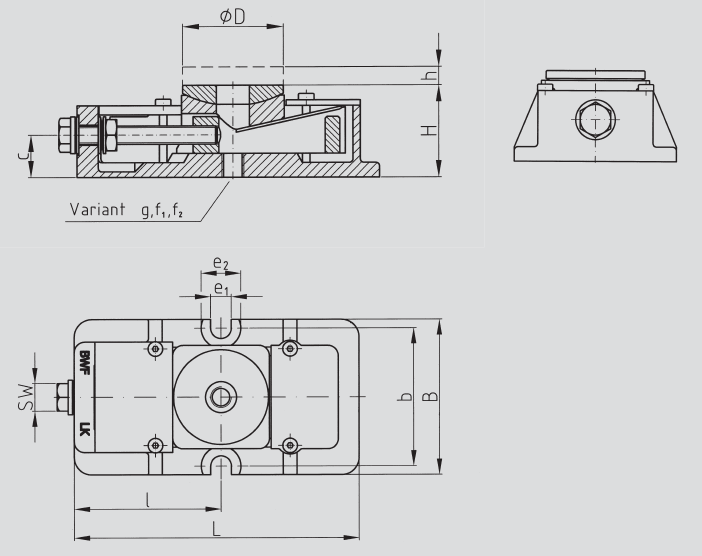

Dimensions of series LK

GA Basic Unit

Technical Data of series LK

| Size | Dim | LK I | LK II | |

|---|---|---|---|---|

| Permissible maximum load | N | 30.000 | 55.000 | |

| Permissible maximum lifting load | N | 20.000 | 40.000 | |

| Torque at adjusting screw | Maximum- | Nm | 20 | 35 |

| Security- | Nm | 3-5 | 4-7 | |

| Vertical Adjustment per screw turn | mm | 0.32 | 0.37 | |

| Weight of basic unit | kg | 2,5 | 4,2 | |

Divide the total load ( machine weight and workpiece ) by the number of bearing points to determine the average load per mount. Select a mount size with an equal or greater recommended static load.

For machinery with sizable variations in partial weight, it is the heaviest machine load that has to be devided by the number of bearing points and the resulting BW-Fixator® size has to be used everywhere under the machine.

Anchor bolts and studs

due

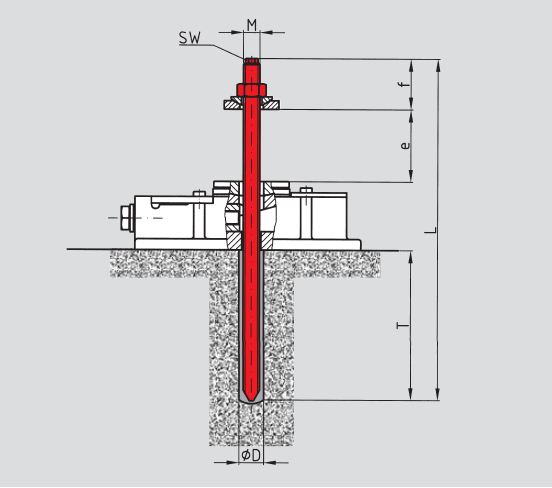

Resin anchor

(Capsule and stud)

| e | Hole | Max. Torque | Clamping Force* | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | M | L | SW | f | von | bis | ØD | T | Nm | max. N | ||||

| I | M12 | 250 | 8 | 30 | 0 | 60 | 14 | 110 | 30 | 10.000 | ||||

| II | M16 | 300 | 10 | 35 | 0 | 80 | 18 | 125 | 60 | 15.000 | ||||

*Concrete ≥ B 25

due/2

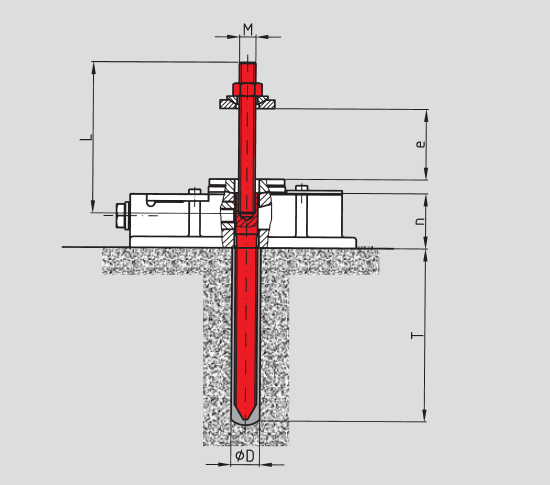

Split resin anchor

(Capsule and split stud)

| e | Hole | Max. Torque | Clamping Force* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | M | L | n | von | bis | ØD | T | Nm | max. N | ||||

| I | M12 | 130 | 40 | 0 | 70 | 18 | 125 | 30 | 10.000 | ||||

| II | M16 | 150 | 40 | 0 | 70 | 18 | 125 | 60 | 15.000 | ||||

*Concrete ≥ B 25

Note: Specify dimension “e” (thickness of machine leg) in your order.

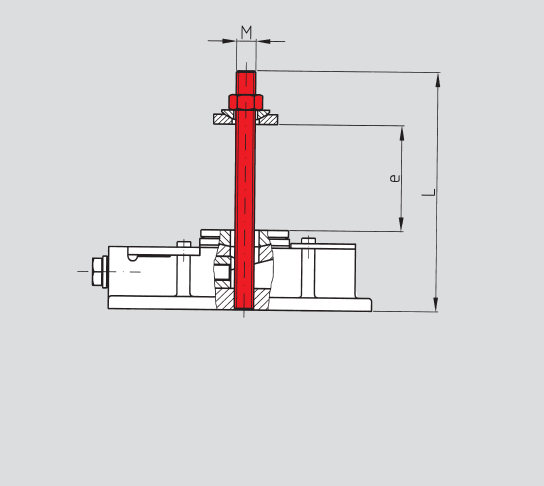

ste

Short or long stud bolt for attaching the machine to the BW-Fixator®

| L | e | L | e | Max. Torque | Clamping Force | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | M | kurz | von | bis | lang | von | bis | Nm | max. N | ||||

| I | M12 | 130 | 0 | 50 | 160 | 55 | 80 | 30 | 10.000 | ||||

| II | M16 | 150 | 0 | 50 | 180 | 55 | 80 | 60 | 15.000 | ||||

Note: Specify dimension “e” (thickness of machine leg) in your order.

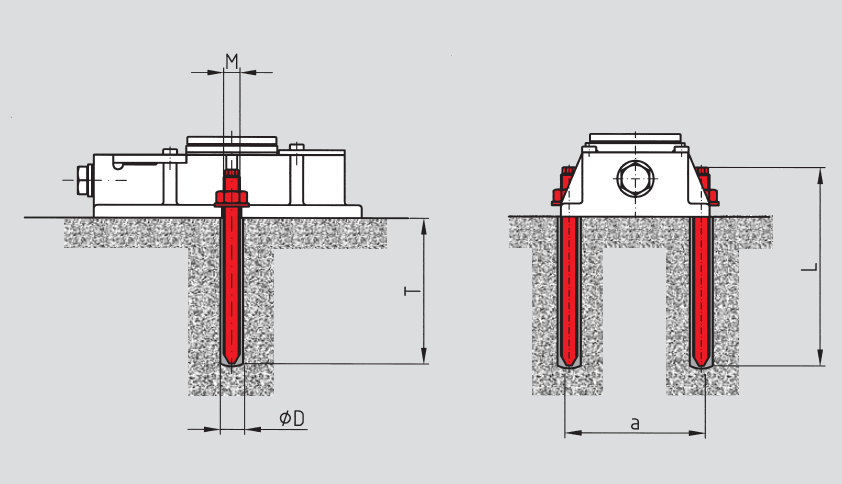

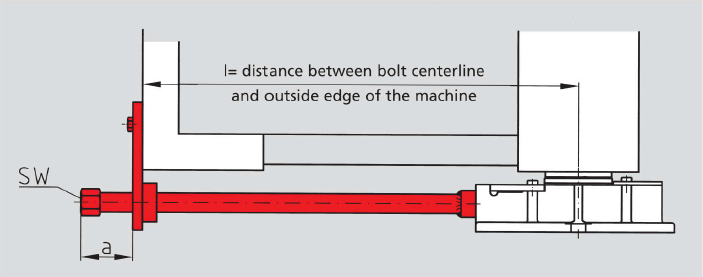

c

Side anchor bolts for connecting BW-Fixator® to the foundation

2 resin anchors and 2 studs

| Hole | Max. Torque | Clamping Force | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | M | L | a | ØD | T | Nm | max. N | ||||

| I | M10 | 130 | 80 | 12 | 90 | 20 | 14.000 | ||||

| II | M12 | 160 | 95 | 14 | 110 | 30 | 20.000 | ||||

Other Applications

le

Extended set screw on BW-Fixator® arranged inwards of the machine side

| length | ||||

|---|---|---|---|---|

| LK | a | SW | min. l | Tube |

| I | 50 | 22 | 140 | 24x4 |

| II | 50 | 22 | 150 | 24x4 |

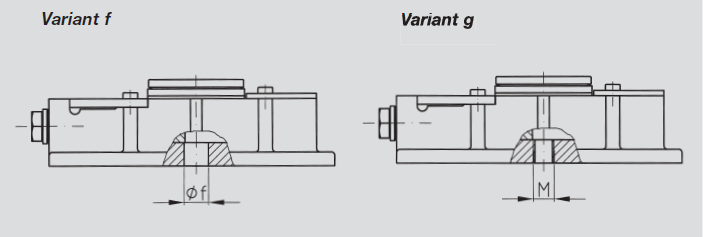

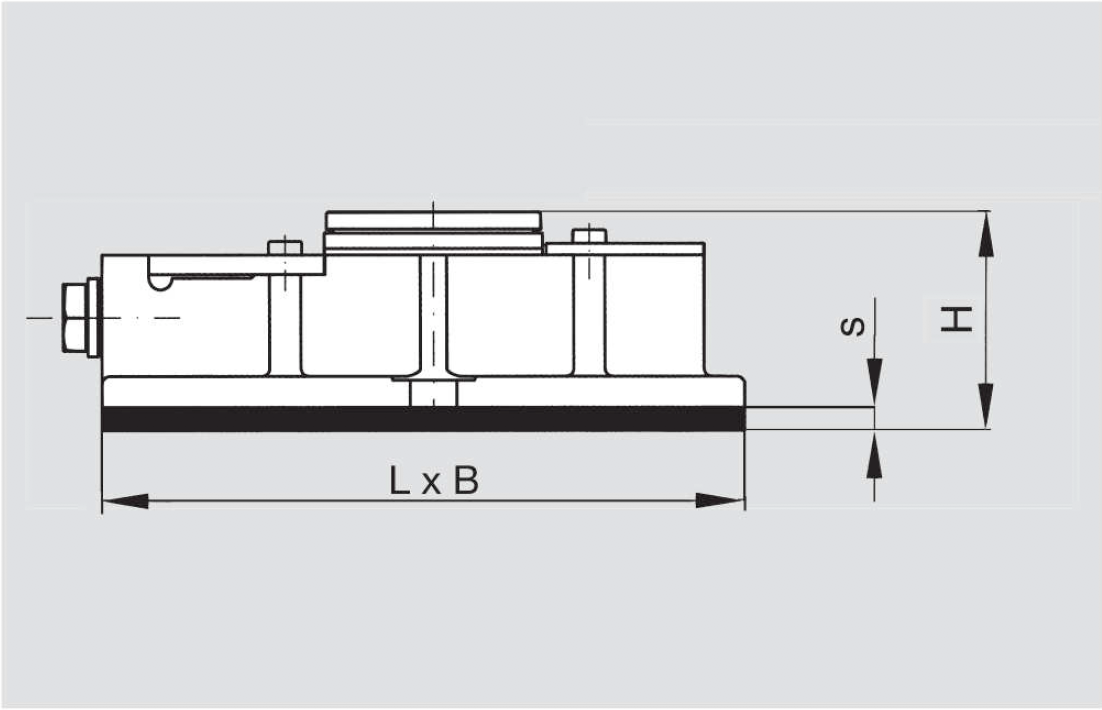

dpl-g-(s)

Isolating plate for not anchored machine installation

thickness s available with 1, 3, 5 mm

Material: bituminous textile

| LK | L | B | H |

|---|---|---|---|

| II | 190 | 107 | 60+s |

Specify in order s and if the plate shall be sticked to the Fixator bottom.

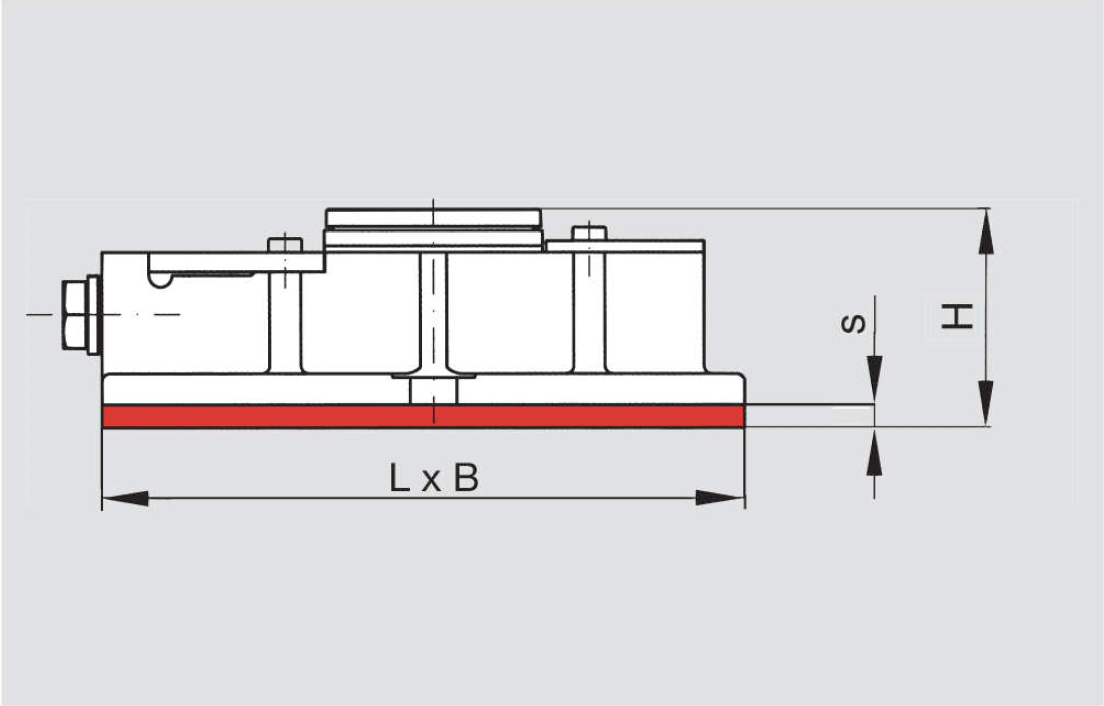

dpl-p

Isolating plate for not anchored machine installation

Material: Polyurethane

| LK | L | B | s | H |

|---|---|---|---|---|

| II | 190 | 107 | 6 | 66 |

The plate is sticked to the BW-Fixator® bottom.

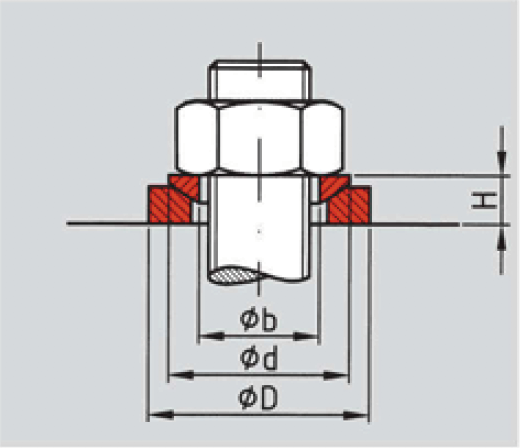

p

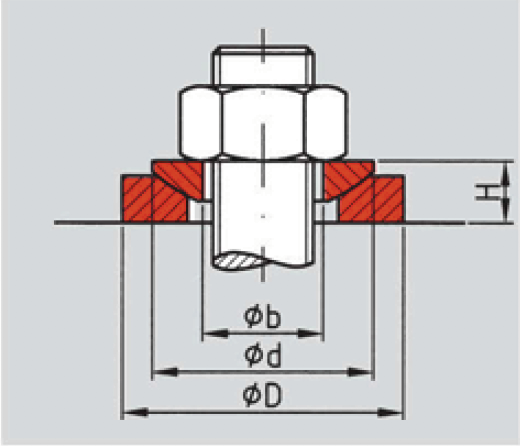

Spherical washer set for non-parallel bearing surfaces

| LK | ØD | H | Ød | b |

|---|---|---|---|---|

| II | 40 | 9 | 30 | 17 |

r

Large spherical washer set for non-parallel bearing surfaces

| LK | ØD | H | Ød | b |

|---|---|---|---|---|

| II | 44 | 10 | 36 | 17 |