Oil Tray Installation with series RK

… for a modern and environment-friendly machine assembly

Worth Knowing

The oil tray installation has been developed especially for the assembly of machine, which produce a large amount of cutting oils and emulsion.These machines have to be built up in oil trays to protect the foundation. Optional the foundation itself can be protected by proper measures e.g. the application of a gradient floor pavement with protective coat and a lead-away gutter.

The oil tray installation has been developed especially for the useage with sheet metal oil trays.

Downloads

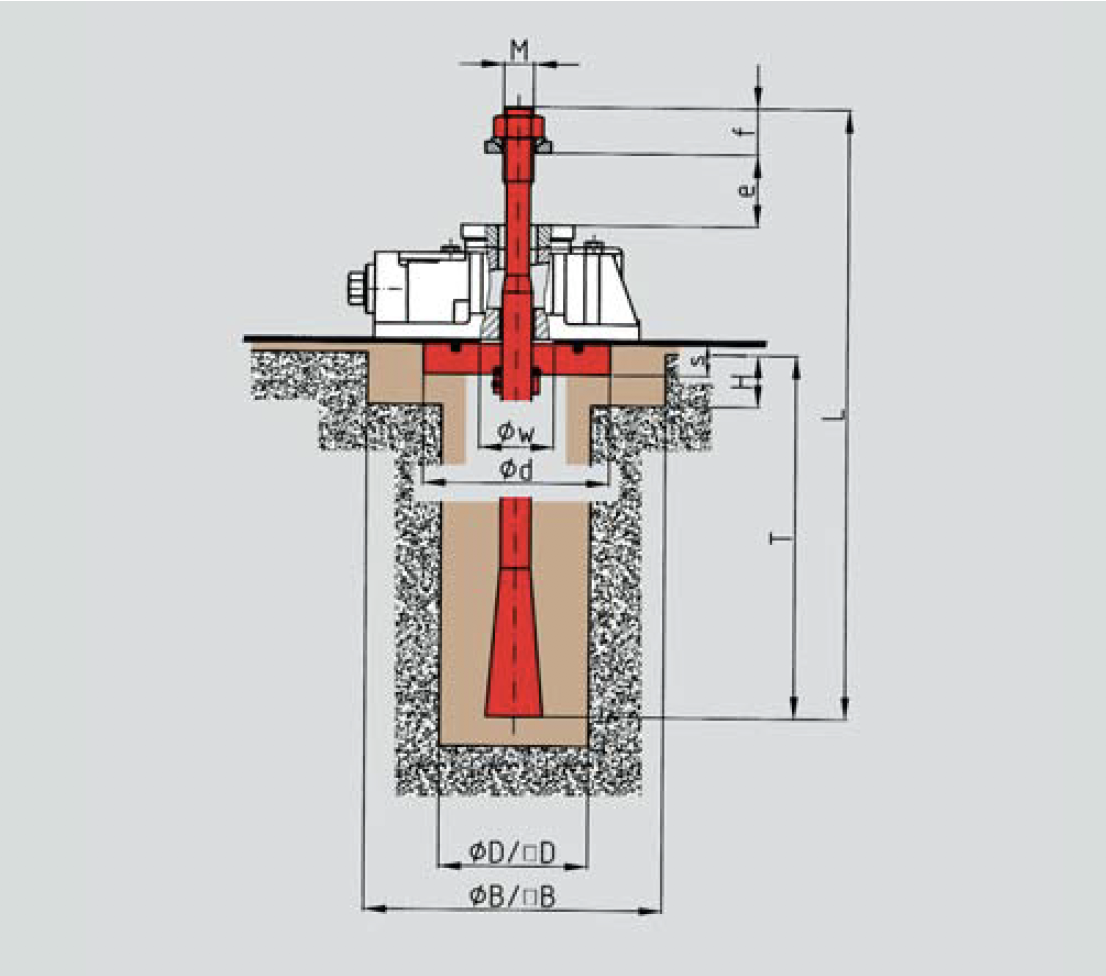

Machine installation with sheet metal oil trays with Serie RK

| e | Foundations | Clamping force | Recommended machine | Permissible | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RK | M | L | Ød | S | f | ØW | von | bis | H | B | D | T | max. N | dead weight N | max. load N | ||||

| I | M16 | 330 | 125 | 15 | 30 | 40 | 20 | 50 | 40 | 200 | 70 | 240 | 53.000 | 10.000 | 90.000 | ||||

| II | M20 | 400 | 125 | 20 | 40 | 40 | 20 | 70 | 40 | 200 | 80 | 270 | 81.000 | 20.000 | 120.000 | ||||

| III | M24 | 500 | 170 | 25 | 50 | 45 | 30 | 90 | 50 | 250 | 100 | 340 | 115.000 | 40.000 | 240.000 | ||||

Note:

Specify the variants f1 and b and dimension „e“ (thickness of machine leg) in your order.

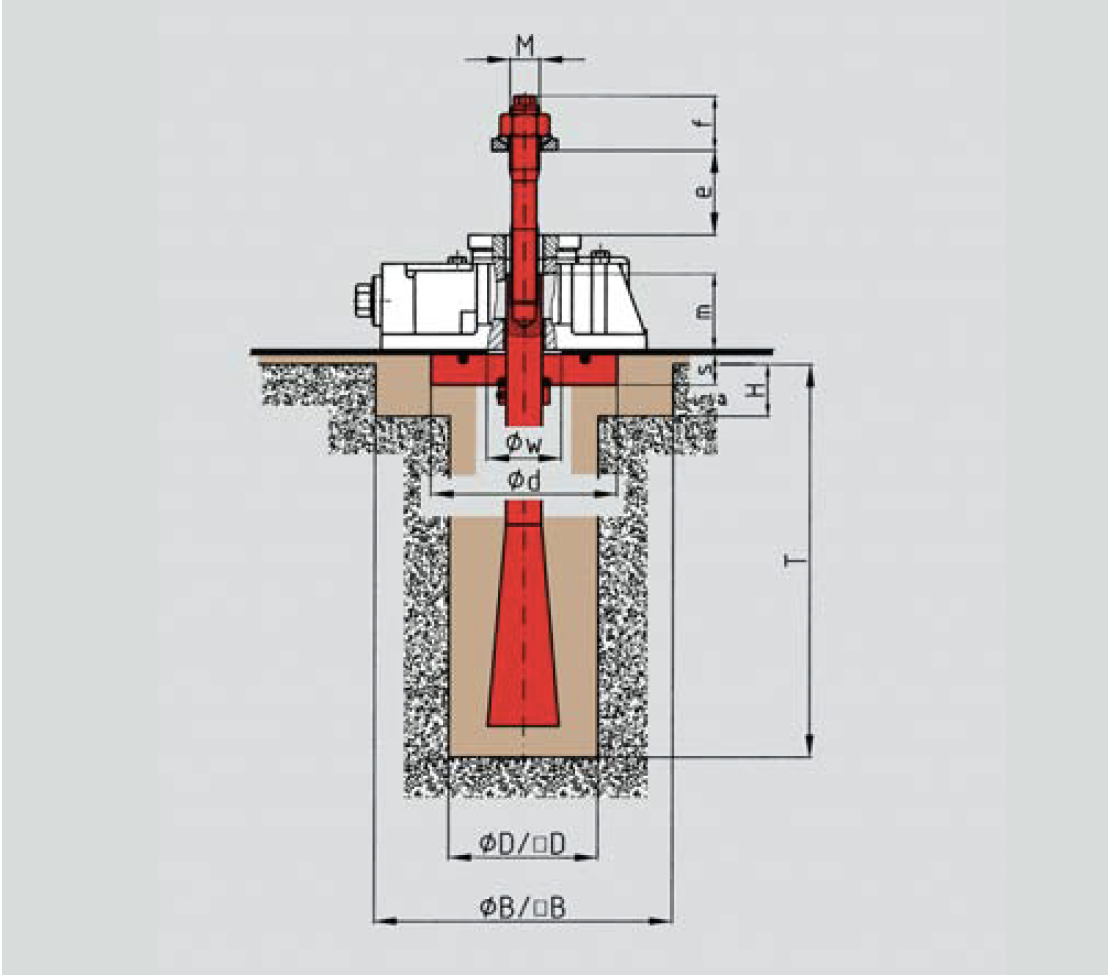

Split Anchor Bolt

Variant (we/2-wu)

Split anchor bolt for direct connection of the machine to the foundation

| Foundations | Clamping force | Recommended machine | Permissible | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RK | M | Ød | S | f | Øw | m | H | B | D | T | max. N | dead weight N | max. load N | ||||

| I | M16 | 125 | 15 | 30 | 40 | 38 | 40 | 200 | 80 | 160 | 53.000 | 10.000 | 90.000 | ||||

| II | M20 | 125 | 20 | 40 | 45 | 50 | 40 | 200 | 100 | 240 | 81.000 | 20.000 | 120.000 | ||||

| III | M24 | 170 | 25 | 50 | 50 | 61 | 50 | 250 | 120 | 320 | 115.000 | 40.000 | 240.000 | ||||

Note:

Specify the variants f2 and b and dimension „e“ (thickness of machine leg) in your order.

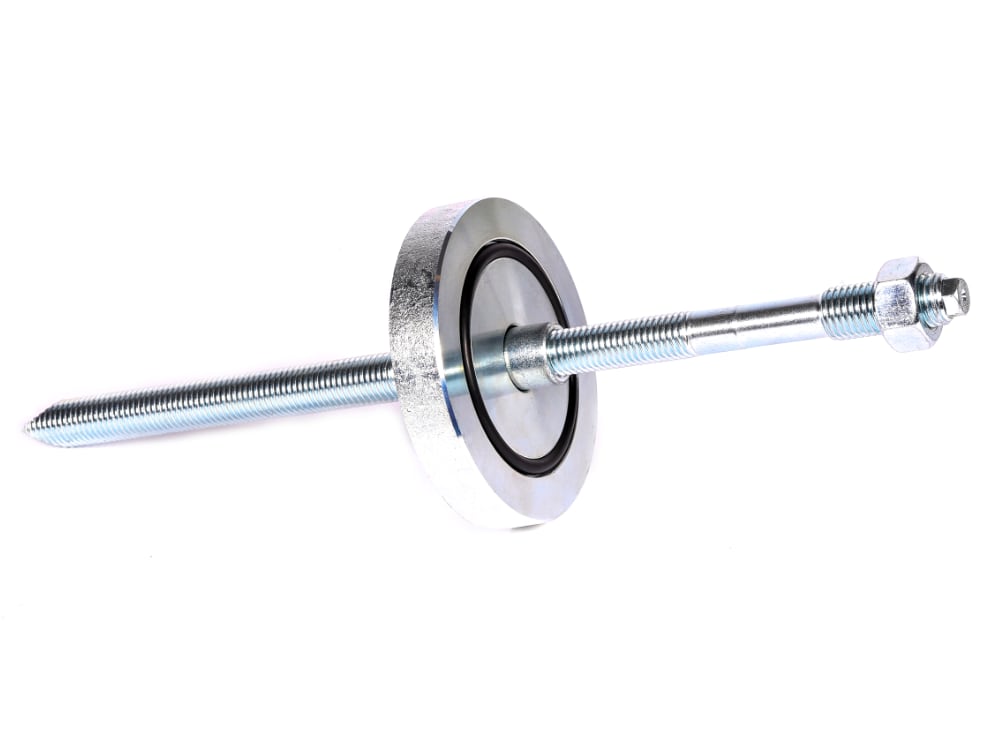

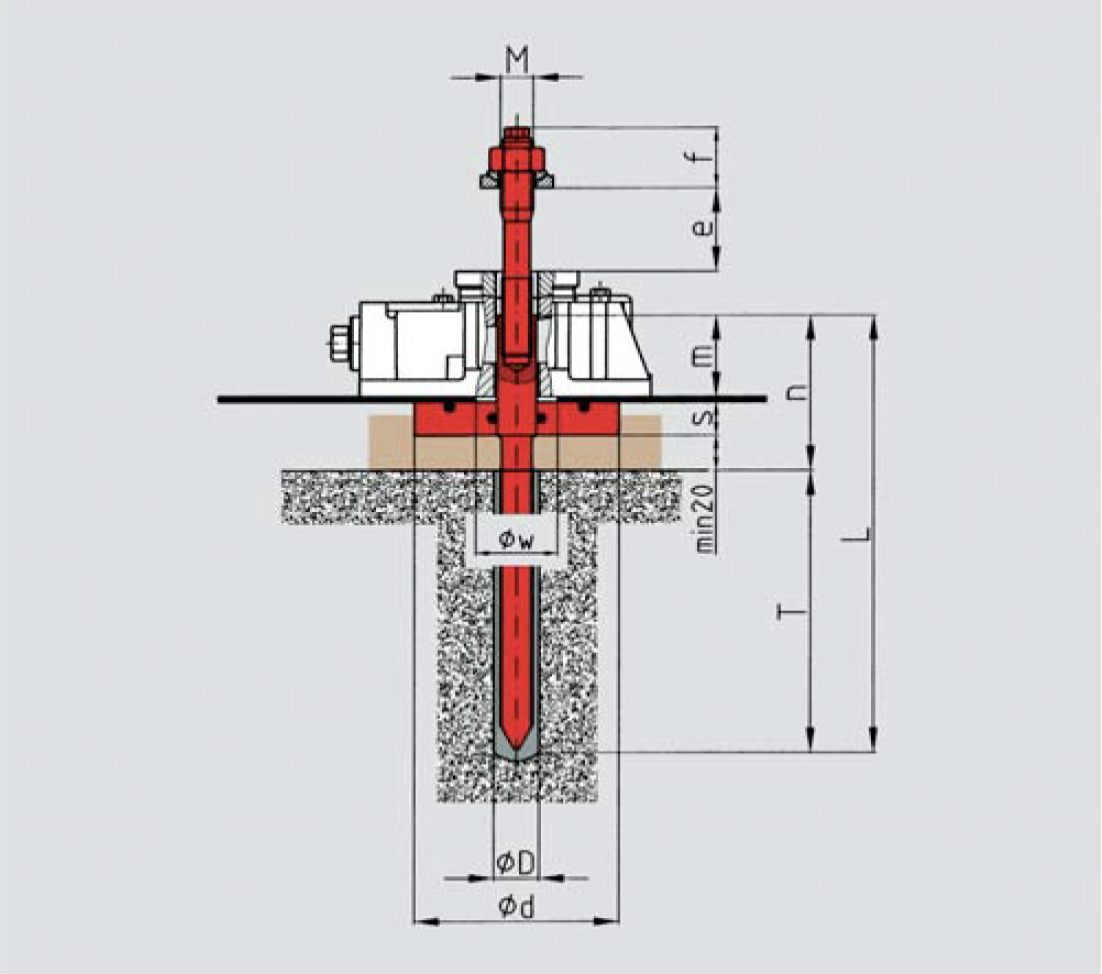

Split Resin Anchor

Variant (due/2-wu)

Split resin anchor for direct connection of the machine to the foundation (Capsule and split stud)

Instruction for installation:

Installing the resin anchors the measure „n“ is to keep as deadline at the highest level of the foundation.

| Foundations | Clamping force | Recommended | Permissible | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RK | M | L | Ød | S | f | ØW | m | n | D | T | max. N | machine dead weight N | max. load N | ||||

| I | M16 | 200 | 125 | 15 | 30 | 40 | 38 | 75 | 18 | 125 | 15.000 | 10.000 | 90.000 | ||||

| II | M20 | 260 | 125 | 20 | 40 | 45 | 50 | 90 | 25 | 170 | 27.000 | 20.000 | 120.000 | ||||

| III | M24 | 290 | 170 | 25 | 50 | 50 | 32 | 80 | 28 | 210 | 37.000 | 40.000 | 240.000 | ||||

Note:

Specify the variants f2 and b and dimension „e“ (thickness of machine leg) in your order.